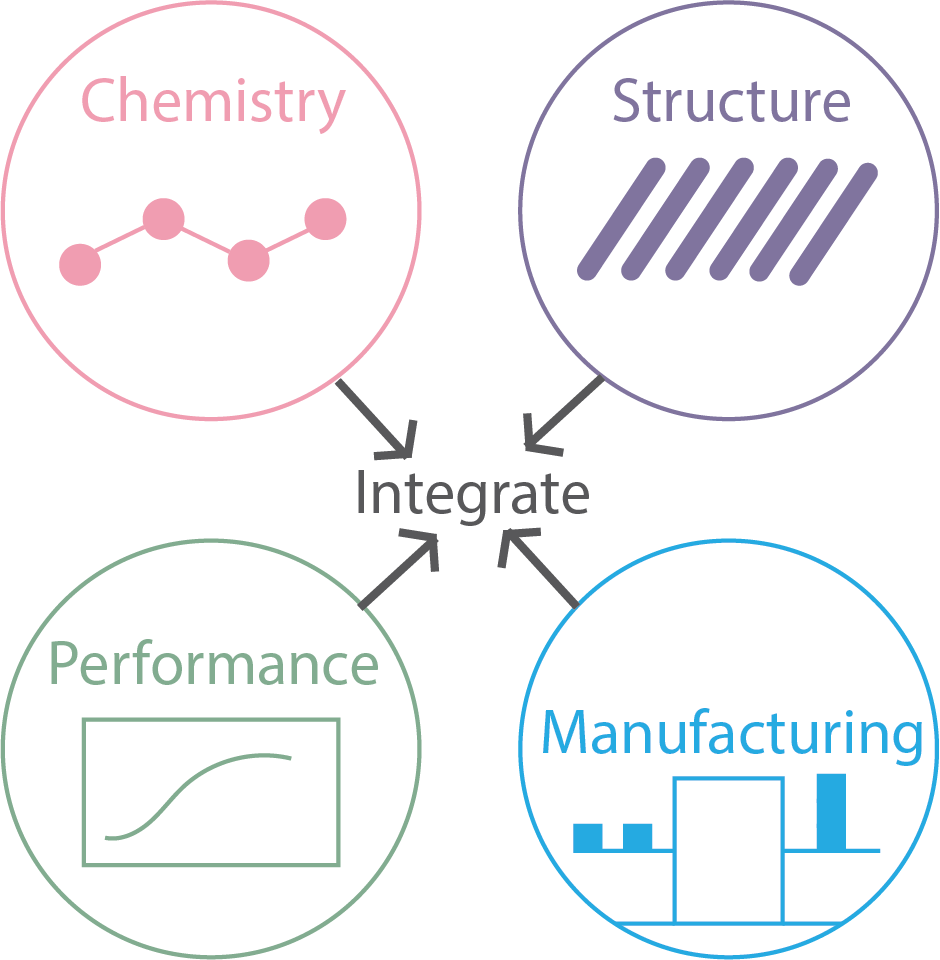

The Brettmann research group focuses on challenges in integrating the product development process, particularly in understanding how the chemistry affects the processing and manufacturability. Traditionally in product development, the chemistry is tied to structure and performance in an R&D lab and then once sufficient performance is reached, scalable manufacturing is addressed, this linear process often results in needing to reformulate a product and delays in commercialization. Important challenges in integrating chemistry through manufacturing include developing an improved understanding of molecular interactions between formulation components, developing a greater ability to handle complex mixtures and increasing use of large data sets in formulation.

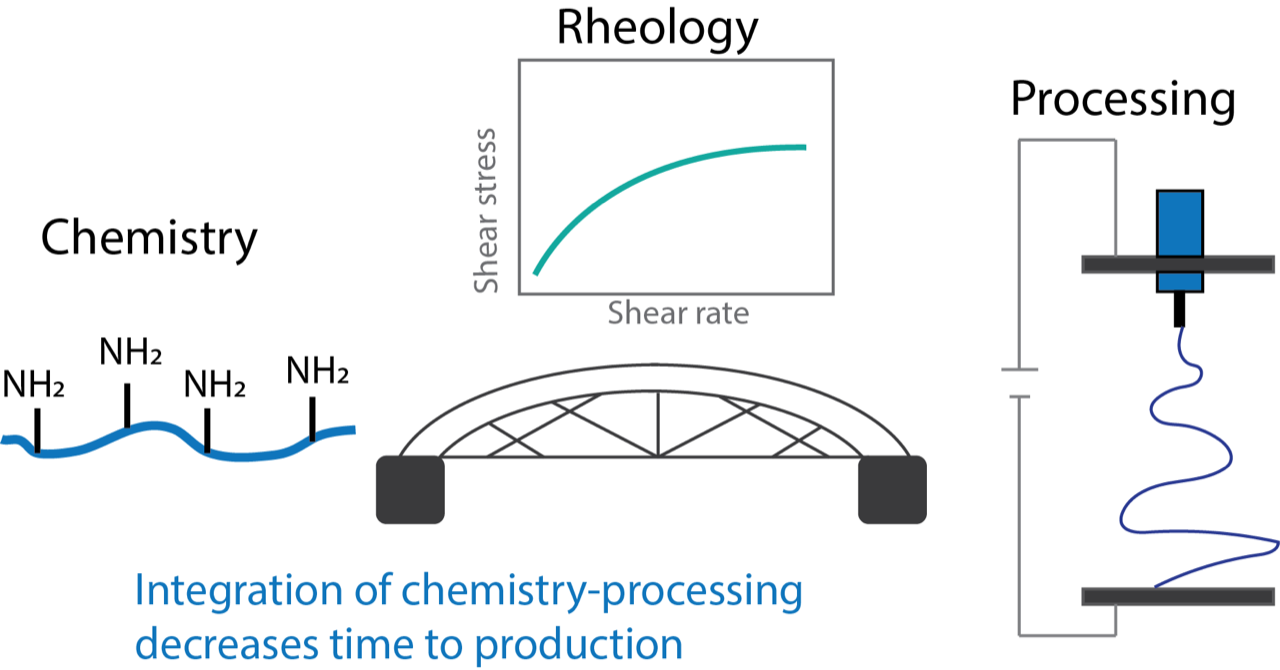

Formulation for Processing

Developing new high performance materials products requires increasingly difficult designs to manufacture, be that ultrafine fibers with complex additives, 3D printed structures with extremely high particle loadings or natural fibers with heterogeneous compositions. We aim to understand how particle characteristics, composition and interactions between components in mixtures impacts processability of those mixtures, often using rheology as a bridge between properties and processability. We aim to improve product design through understanding manufacturability using key processing techniques such as electrospinning, 3D printing and blade and slot die coating.

Representative Publications:

Ewaldz E., Patel R., Banerjee M., Brettmann B. (2018). Material Selection in Electrospinning Microparticles. Polymer, 153, 529-537. https://www.sciencedirect.com/science/article/abs/pii/S0032386118307183

Woods, H., Boddorff, A., Ewaldz, E., Adams, Z., Ketcham, M., Jang, D.J., Sinner, E., Thadhani, N. and Brettmann, B. (2019), Rheological Considerations for Binder Development in Direct Ink Writing of Energetic Materials. Prop., Explos., Pyrotech., 44, 1-11. https://onlinelibrary.wiley.com/doi/epdf/10.1002/prep.201900159

Campbell, I., Marnot, A., Ketcham, M., Travis, C., Brettmann, B. Direct ink write 3D printing of high solids loading bimodal distributions of particles. AIChE J. 2021;e17412.

https://aiche.onlinelibrary.wiley.com/doi/abs/10.1002/aic.17412

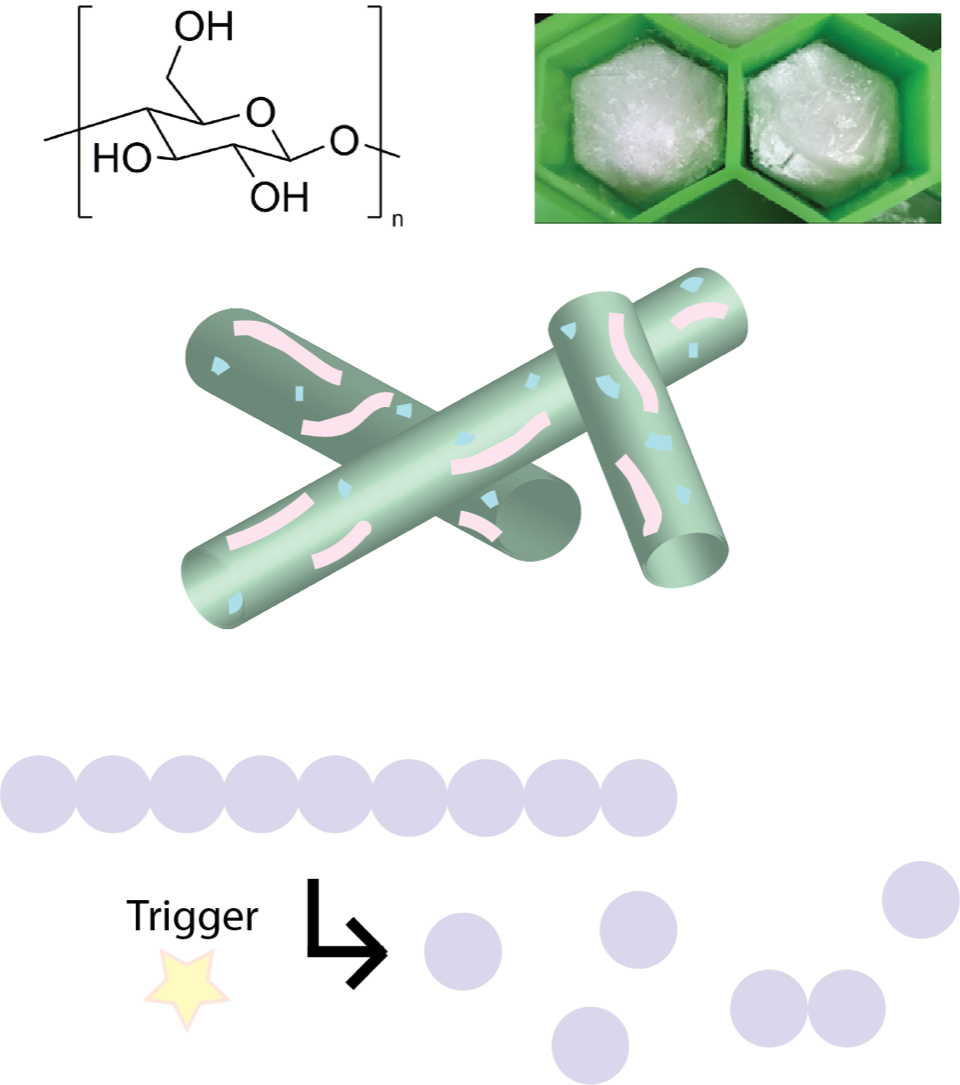

Sustainable Polymeric Materials

Renewably sourcing components of polymeric materials and improving end-of-life practices for plastics is essential to increasing the sustainability of everyday material goods. We use our expertise in polymers and formulation to understand how to best integrate cellulose materials into products and how to process and use depolymerizable polymers and degradable composites. From new polymer and composite design to computation/experimental collaboration for predicting molecular behavior to approaches to degrade complex multicomponent plastic waste, we aim to solve sustainability challenges through an understanding of molecular and structural characteristics of materials.

Representative Publications:

Banerjee, M., Saraswatula, S., Williams, A., Brettmann, B. (2020), Effect of Purification Methods on Commercially Available Cellulose Nanocrystal Properties and TEMPO Oxidation. Processes, 8 (6), 698. https://www.mdpi.com/2227-9717/8/6/698/html

Khan, N., Zaragoza, N. Z., Travis, C. E., Goswami, M., Brettmann, B. K. (2020), Polyelectrolyte Complex Coacervate Assembly with Cellulose

Nanofibers. ACS Omega. https://pubs.acs.org/doi/pdf/10.1021/acsomega.0c00977